Insights

Transform Data into Actionable Insights

Leverage advanced analytics and intuitive visualization tools to uncover patterns, optimize performance, and make smarter, data-driven decisions.

Data Insight Applications

-

Insights

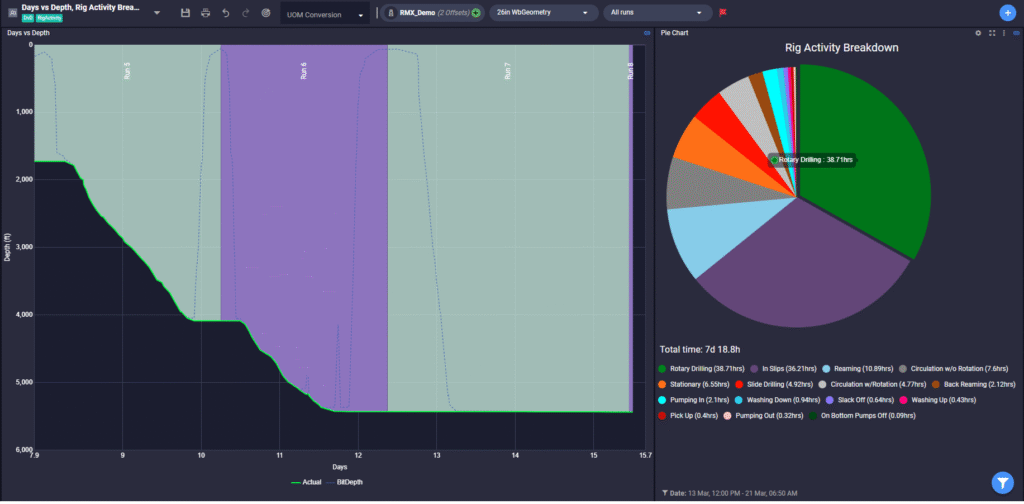

RigMetrix ™

RigMetrix turns hidden inefficiencies into measurable insights. With a large library of drilling and tripping KPIs, RigMetrix empowers rig site crews, drilling engineers, and asset managers to uncover Invisible Lost Time (ILT) and monitor Non-Productive Time (NPT). It enables fast, data-driven decisions, and helps teams reduce cost per foot and time per foot while boosting operational efficiency.

-

Streamline analysis of drilling, tripping, and casing operations with a flexible, browser-based application.

-

Utilize built-in and user-defined KPIs to perform granular analysis across drilling phases - from spud to TD - enabling continuous performance improvement.

-

Compare crew and rig performance using filters, grouping options and offset wells to highlight best practices and improvement areas.

-

Utilize user defined performance targets to identify Invisible Lost Time (ILT) reduction opportunities.

-

Insights

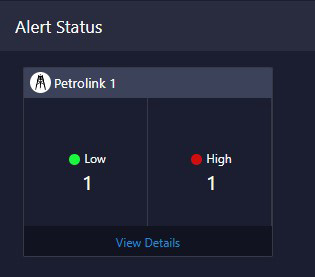

Manage By Exception ™

Manage By Exception delivers real-time alerts when predefined conditions are met, so users don’t have to manually monitor trends. Whether it’s data quality issues, drilling anomalies, geological or downhole events, the system intelligently routes notifications to the right teams via SMS, email, or in-app messages, enabling one person to monitor multiple rigs with confidence.

-

Use real-time algorithms to continuously monitor wellbore conditions.

-

Send targeted alerts via PetroVue Mobile, email or SMS.

-

Prioritize notifications to ensure critical issues get immediate attention.

-

Help teams take timely preventive actions to improve safety and reduce Non-Productive Time (NPT).

-

Snooze and acknowledge alerts with comments visible to all.

-

Audit historical alerts.

-

Use the existing rule library to deploy alerts.

-

Insights

DrillAct ™

Building engineering applications from scratch can be time-consuming and complex. DrillACT simplifies this with ready-to-use applications – like Torque and Drag, Flowback Fingerprinting, and Trip Sheet – that can be easily customized to fit specific operational needs. Moreover, custom applications can be quickly configured using a library of widgets and combined with engineering calculations to accelerate insight generation and improve drilling performance.

-

Leverage ready-to-use applications such as Torque and Drag, Flowback Fingerprinting, and Driller's Blueprint.

-

Integrate engineering models such as friction and hydraulics for advanced analysis.

-

Build custom applications with a user-friendly, widget-based interface.

-

Share your custom applications with other users for easy collaboration.

-

Insights

Torque and Drag

For well monitoring specialists and drilling engineers, detecting downhole issues during tripping and drilling is critical to avoiding costly delays. DrillACT’s Torque and Drag application enables real-time comparison of friction factor models and BHA runs, helping engineers spot anomalies early and optimize performance. With a customizable interface — including standard broomstick plots — the Torque and Drag solution adapts to diverse operational needs, reduces risk and downtime, and improves well execution.

-

Compare real-time torque and hookload data with friction factor models to detect downhole issues early.

-

Easily compare data between drilling and tripping runs.

-

Visualize hookload and torque along with formation markers to identify trends.

-

View raw data along with aggregation options such as average, minimum and maximum to aid with the analysis.

-

Standardize and manage model data.

-

Insights

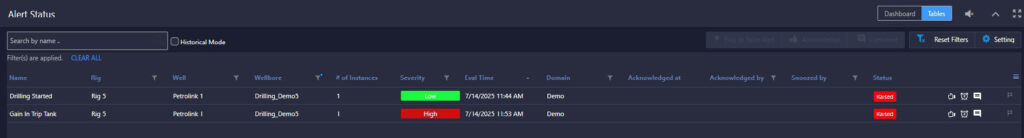

Flowback Fingerprinting

For well monitoring specialists and drilling engineers, spotting flowback anomalies during pumps-off operations is vital for safety and efficiency. Flowback Fingerprinting enables real-time trend comparison against historical data, helping users quickly detect deviations. With customizable thresholds and in-app alerts, the solution enhances operational awareness, reduces risk, and supports faster, more informed decision-making.

-

Monitor flow rate along with the flowback volume going into active tanks and tripping tanks.

-

Visualize and compare live and historical flowback events.

-

Setup user defined thresholds to detect anomalies in real-time.

-

Automated alerts for gain/loss trends, kicks, and influx risks.

-

Supports custom profiles and historical alert reviews to improve wellsite safety and response.

-

Insights

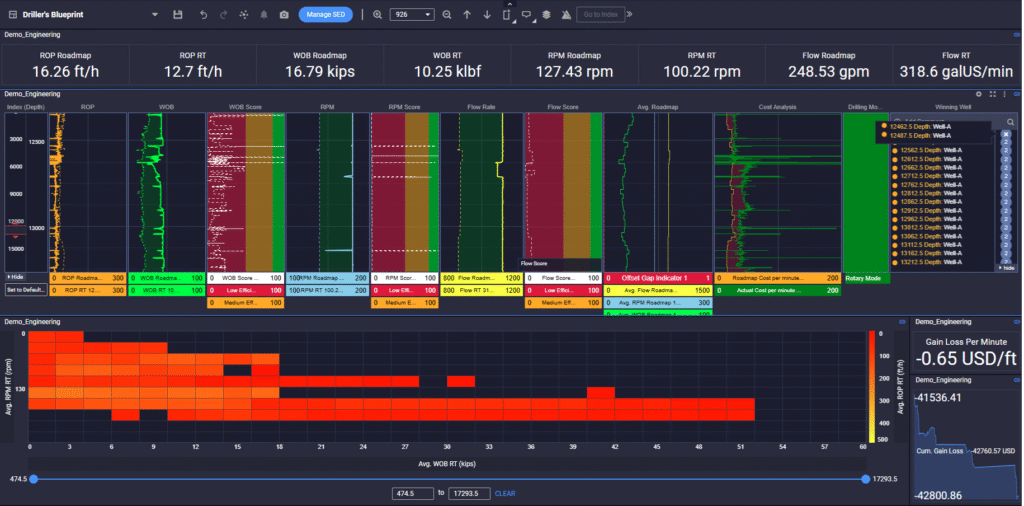

Driller's Blueprint

Driller’s Blueprint equips drilling engineers with a data-driven roadmap, analyzing historical offset well data to reveal the ideal drilling parameters (WOB, Flowrate and RPM) that will boost efficiency and speed. This directly translates into significant reductions in drilling costs and valuable rig time. Moreover, the system offers real-time performance monitoring against established benchmarks, providing actionable visual alerts for any deviations, enabling engineers to swiftly course-correct and enhance overall profitability.

-

Maximize Rate of Penetration (ROP) by optimizing WOB, RPM, and flow rate.

-

Benchmark drilling parameters against the optimal operating window.

-

Score performance by section and formation to identify gaps.

-

Use heatmaps to visualize the most effective parameter combinations.

-

Insights

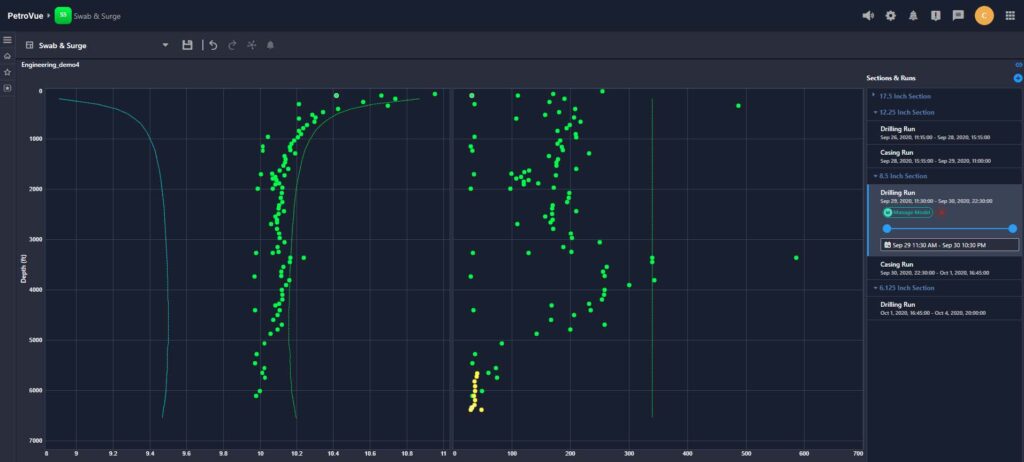

Swab and Surge

The Swab and Surge solution helps drilling teams proactively manage wellbore pressure during tripping operations. By calculating Equivalent Static Densities (ESD) in real-time, the system immediately compares operations against well fracture gradients and pore pressure limits. This confidently ensures wellbore stability by preventing costly issues like lost circulation and influxes, directly leading to reduced Non-Productive Time, safer operations, and enhanced drilling efficiency.

-

Monitor Equivalent Mud Weight (EMW) in real-time and ensure that running speeds stay within safe limits.

-

Compare EMW with modelled fracture and pore pressures to prevent well control issues caused by lost circulation influx or formation breakdown.

-

Insights

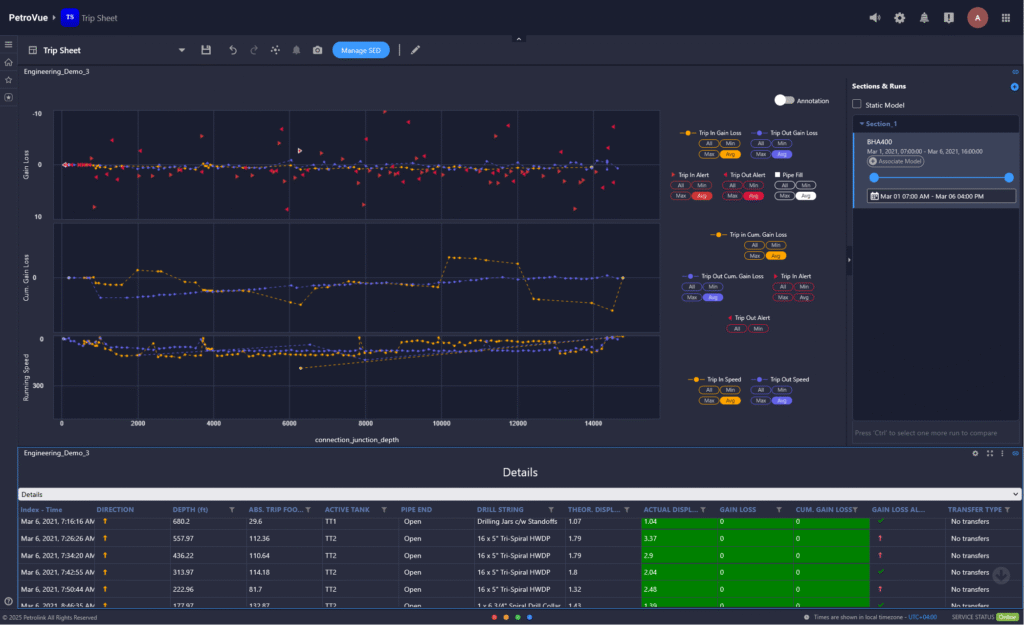

Trip Sheet

Trip Sheet supports drilling teams with accurate analysis of volumetric exchanges during tripping operations, directly replacing the complexities of time consuming manual spreadsheet analysis. It quantifies displacement differentials and fluid transfers, alerting drillers to developing wellbore influxes or losses. This mitigates the risk of severe wellbore instability and blowouts, avoiding extensive operational downtime and enabling a safer, more productive drilling program.

-

Analyze flowback data in real-time to detect fluid gains/losses.

-

Track tripping speeds against safety limits and visualize per-stand and cumulative metrics.

-

Monitor trip tanks, active systems, and receive threshold-based alerts.

-

Customize tabular displays and range sorting for an efficient review.

-

Eliminate manual trip sheets to reduce errors and save time.

-

Accurately log gains, losses, and drag per stand for better operational decisions.

-

Perform manual corrections on the calculated data and subsequently execute on-demand recalculations.

-

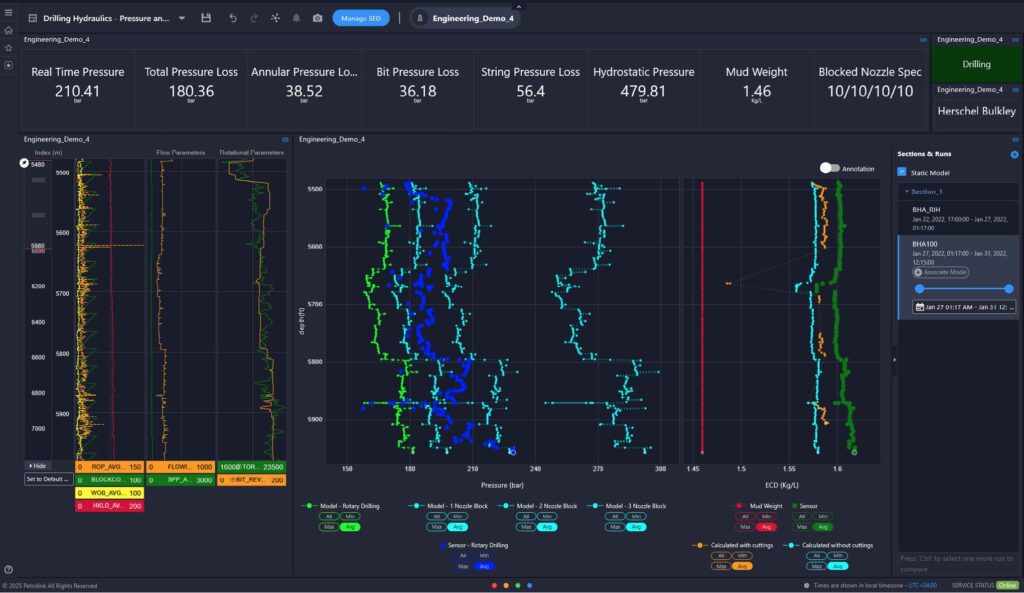

Insights

Hydraulics

The Hydraulics solution provides a real-time understanding of your wellbore’s circulatory system by delivering insights into critical factors like pressure losses, Equivalent Circulating Density (ECD), cuttings transport, and even modeling the immediate impact of blocked nozzles. This aids in making smarter, data-driven decisions by comparing planned hydraulic models with actual downhole conditions. Consequently, it prevents critical issues such as lost circulation, kicks, and stuck pipe, leading to optimized drilling efficiency, reduced Non-Productive Time, and enhanced operational safety.

-

Compare real-time ECD with mud weight and modeled values to optimize wellbore pressure.

-

Visualize pressure losses across the string, bit, and annulus for better drilling control.

-

Match live standpipe pressure data with model predictions to spot inconsistencies early.

-

Simulate nozzle configurations to evaluate pressure scenarios and tool performance.

-

Choose from multiple fluid models and tailor analysis to specific well conditions.

-

Insights

Hole Cleaning

The Hole Cleaning solution addresses the challenge of cuttings accumulation by providing real-time insights into cuttings transport across all well sections. It calculates crucial metrics like slip and transport velocities to determine the minimum flow rates needed for effective cuttings removal and delivers an index representing the hole cleaning status. This prevents stuck pipe, lost circulation, and Non-Productive Time for optimized drilling.

-

Prevent stuck pipe and drilling inefficiencies by improving hole cleaning.

-

Monitor annular velocity and cuttings transport in real-time.

-

Compare actual versus required cleanup cycles to optimize performance.

-

Insights

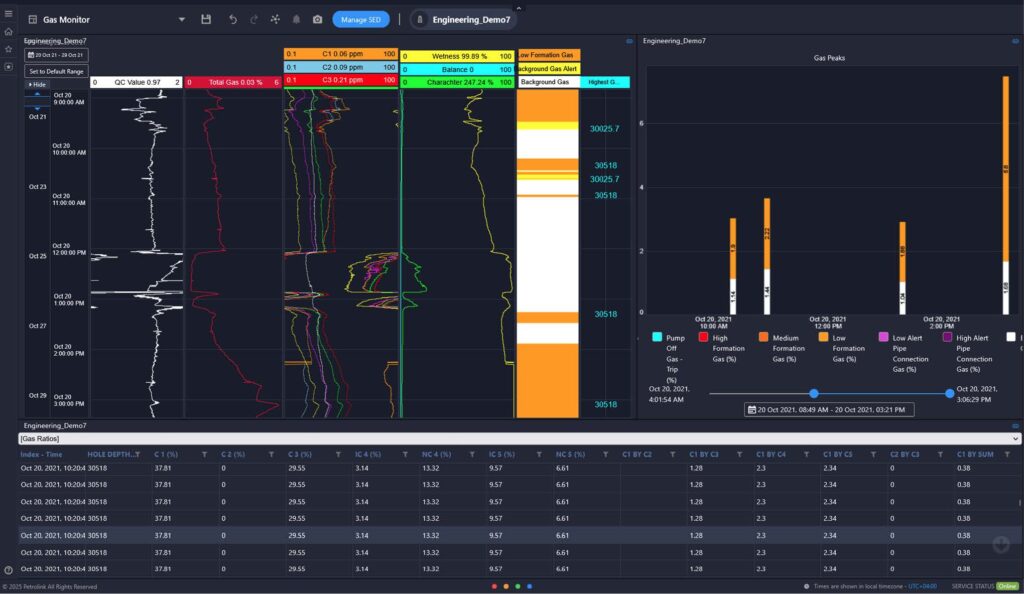

Gas Monitoring

The advanced Gas Monitoring solution provides real-time insights into downhole wellbore behavior by automatically identifying and classifying critical gas trends like connection gas and formation gas peaks. It significantly reduces hazardous situations by minimizing the risk of both formation fracture and unexpected influx. By optimizing drilling fluid, costly well control incidents such as lost circulation and Non-Productive Time are prevented, allowing for safer, optimized drilling.

-

Monitor and classify real-time gas peaks to identify composition changes.

-

Analyze gas chromatograph data, key ratios, and depth-indexed gas parameters for zone identification.

-

Pinpoint reservoir zones and compare current versus historical gas profiles to enhance interpretation.

-

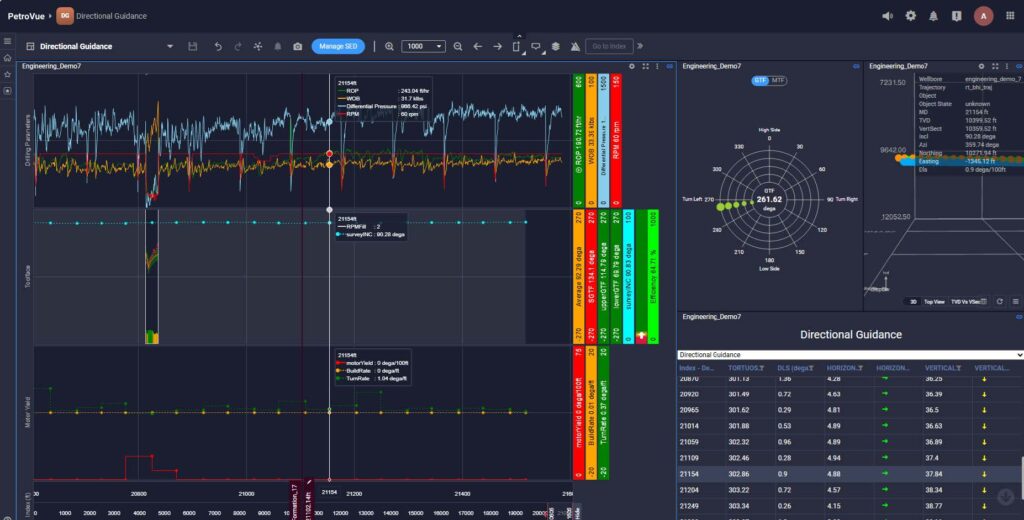

Insights

Survey Guidance

The Survey Guidance solution eliminates guesswork in directional drilling by predicting mud motor steering behavior in real-time — using formation properties and drilling parameters. This reduces sliding time, accelerates target depth achievement, and minimizes wellbore tortuosity. Unlike traditional tools, it also quantifies real-time survey deviation, so you know exactly how far off-plan your well is and can correct instantly.

-

Automatically analyze deviation, drift, tortuosity, and motor yield to assess directional control.

-

Customize displays with key drilling parameters like depth, inclination, and azimuth.

-

Use the Steering Rose widget and tooltips to manage wells and investigate data points.

-

Add offset wells and track deviations from the main borehole in real-time.

-

Compare wellbores in 3D to validate trajectory and improve directional planning.